Different Approaches to Capturing Industrial Carbon

As the world grapples with the urgency of climate change, effective carbon capture from industrial sources has become a cornerstone strategy for reducing greenhouse gas emissions. Industrial facilities—such as power plants, steel mills, and cement factories—are among the largest contributors to carbon dioxide emissions. Capturing this carbon before it enters the atmosphere is critical to meeting global climate goals. In this blog, we’ll explore various approaches to capturing industrial carbon, how they work, and their potential to transform heavy industries.

What Is Carbon Capture?

Carbon capture refers to the process of trapping carbon dioxide (CO₂) produced by industrial activities before it’s released into the atmosphere. The captured CO₂ can then be stored underground or reused in other industrial applications. By preventing emissions at the source, carbon capture plays a key role in mitigating the impacts of climate change.

One major category of solutions focuses on enhancing co2 capture technologies, which include a mix of proven and emerging methods designed to suit different industries and emission profiles.

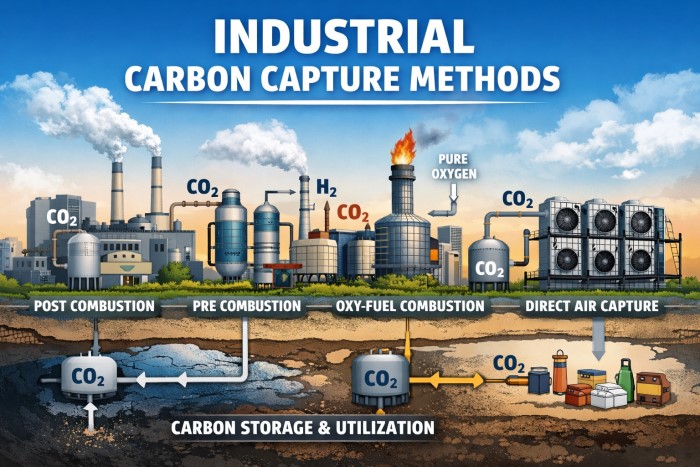

Post‑Combustion Capture

Post‑combustion capture is among the most established carbon capture methods. In this approach, CO₂ is separated from the flue gases produced after fossil fuels are burned. These flue gases are typically a mixture of nitrogen, water vapor, and carbon dioxide.

To extract the CO₂, chemical solvents or solid sorbents are used to bind with the carbon dioxide molecules. Once bound, the CO₂ is heated or depressurised to release it from the solvent, resulting in a concentrated stream of CO₂ ready for compression and storage.

One advantage of post‑combustion systems is that they can be retrofitted onto existing power plants and industrial facilities without major changes to the core process. However, they do require significant energy input to regenerate the solvents, which can impact overall efficiency.

Pre‑Combustion Capture

Pre‑combustion capture is more commonly associated with integrated gasification combined cycle (IGCC) plants and hydrogen production processes. In this method, fuel is converted into a mixture of hydrogen and carbon monoxide through gasification. The carbon monoxide is then shifted into CO₂ and hydrogen using a water‑gas shift reaction.

Once the CO₂ is separated, the remaining hydrogen can be used as a low‑carbon fuel. Pre‑combustion capture tends to be more efficient than post‑combustion because CO₂ is removed at higher pressure and concentration. However, this approach is typically more suitable for new facilities rather than retrofitting existing ones.

Oxy‑Fuel Combustion

In oxy‑fuel combustion systems, industrial processes burn fuel with pure oxygen instead of air. Because nitrogen—a major component of air—is removed, the exhaust gas primarily consists of CO₂ and water vapor. After cooling, the water vapor condenses, leaving behind a relatively pure stream of CO₂.

The key benefit of oxy‑fuel combustion is the simplicity of the CO₂ separation step. On the downside, producing pure oxygen requires energy and infrastructure, which can add cost and complexity.

Direct Air Capture

Unlike the previous methods that target emissions at the source, direct air capture (DAC) removes CO₂ directly from the atmosphere. This technology uses chemical sorbents or filters to bind CO₂ from ambient air. Once captured, the CO₂ can be stored underground or utilised in industrial products.

While DAC offers the exciting potential of achieving negative emissions, it’s currently more energy‑intensive and costly than capturing CO₂ directly from industrial flue gases. Continued innovation and scaling are essential to making DAC economically viable.

Emerging and Hybrid Solutions

Innovations in carbon capture continue to evolve. Research is exploring advanced solvents, solid adsorbents, membrane separation, and biological approaches using algae or engineered microbes. Some systems combine methods to target specific industries or operational needs.

For example, integrating carbon capture with utilisation—where captured CO₂ is turned into fuels, chemicals, or construction materials—not only reduces emissions but also creates economic value.

Conclusion

Capturing carbon from industrial sources is a multifaceted challenge that requires a portfolio of solutions. From established methods like post‑ and pre‑combustion capture to emerging technologies like DAC and hybrid systems, each approach has strengths and trade‑offs. As the technology matures and investment grows, industrial carbon capture will play an increasingly vital role in building a sustainable, low‑carbon future.