The Future of Wood Estimation in Modern Project Design

The manner wooden is quantified and planned is evolving unexpectedly. Digital equipment, collaboration structures, and remark loops are transforming wooden estimation from a guide technique into a strategic functionality. Accurate, facts-driven estimates now power budgets, schedules, and sustainability consequences.

1. Why are precision subjects more than ever

Precision in material planning reduces risk, tightens budgets, and improves buildability. As initiatives develop greater complex and customers demand greater transparency, a unmarried miscount or mis-specification can cascade into luxurious delays. Accurate early-level quantities assist groups in locking in practical procurement schedules, reducing garage desires, and limiting on-site waste.

When estimating is handled as a strategic asset in preference to an administrative project, groups can take a look at layout alternatives, forecast cost glide, and make informed trade-offs among value and performance. The future of wooden estimation begins with a dedication to measurable accuracy — not guesses — and with equipment that makes the measurements repeatable throughout initiatives.

2. From drawings to dynamic fabric intelligence

The shift from static drawings to dynamic material fashions is valuable to modern estimation. Automated extraction equipment accelerates the conversion of plans into quantifiable lists, and it makes it easy to simulate specific framing schemes or material substitutions.

For instance, walking a virtual lumber takeoff without delay from a BIM model yields unique period and count information in minutes, which can then be adjusted for nearby grading guidelines or dealer-unique sizes. Designers can iterate fast, estimators validate assumptions, and procurement can line up suppliers sooner.

As those systems evolve, estimates will deliver richer metadata — recommended reduce patterns, endorsed % sizes, or even carbon impact — transforming an easy quantity list into actionable intelligence.

3. Collaboration and the role of specialized partners

Integrated workflows require more than gear; they require collaboration. Estimators, designers, fabricators, and location supervisors have to percentage a common dataset and revision records so choices are traceable and reversible.

For many corporations, specifically the ones scaling unexpectedly or tackling unfamiliar challenges, engaging an external professional is fantastic. A relied on Construction Estimating Company brings curated price libraries, superior takeoff processes, and skilled estimators who translate design reason into dependable, dealer-conscious portions.

This partnership allows internal groups to remain focused on transport at the same time as outside professionals manage baseline estimates and complicated scopes effectively.

4. Embedding comments loops among the site and the workplace

The quality estimates develop smarter with each challenge. Capturing actual-global results — what turned into genuinely used, damaged, or returned — and feeding that information back into estimating templates closes the loop between prediction and fact.

Mobile reporting tools and barcode-enabled manifests permit crews to log usage in real time, permitting fast reconciliation and enhancing future forecasts. Over time, these feedback loops lessen variance between envisioned and real consumption, tighten procurement margins, and provide a factual basis for non-stop technique development.

5. Standardization, automation, and packaged offerings

Scaling estimation capability calls for standardization and automation. Creating libraries of confirmed assemblies, waste elements, and supplier profiles ensures steady assumptions throughout tasks whilst freeing estimators to recognition on exceptions and high-risk items.

As this functionality matures, companies can package their expertise into formal Construction Estimating Services. These services provide scenario analyses, buildability consultations, and procurement roadmaps, transforming raw quantity facts into actionable advice. Clients benefit from transparency and selection-ready alternatives that provide stability in price, schedule, and sustainability.

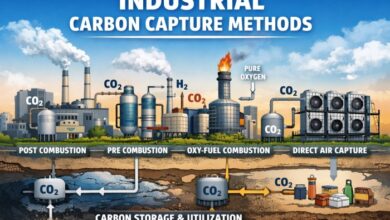

6. Sustainability, traceability, and the data-driven gain

Modern clients anticipate cost certainty and environmental accountability. Advanced estimation structures now aid lifecycle tests and traceability, permitting teams to compare embodied carbon throughout wooden alternatives and select species or engineered products that meet overall performance and sustainability goals.

Traceability strengthens procurement: understanding which dealer batch or mill a piece of wood came from improves assurance claims and helps reuse or recycling strategies. Firms that leverage records for each monetary and environmental price are higher positioned for future tenders and partnerships.

Read More. How Much Does Composite Decking Cost in 2025?

7. Final thoughts

The future of wooden estimation is records-rich, collaborative, and outcome-centered. It transforms the profession from reactive counting to proactive planning, in which each estimate is a situation, every amount carries context, and every build contributes comments to the subsequent undertaking.

Achieving this requires making an investment in computerized extraction, institutionalizing subject comments, and — whilst necessary — partnering with professional estimators to bridge functionality gaps. Teams that adopt these practices will lessen waste, lower prices, and unlock new purchasing price through transparency, predictability, and sustainability.